CNC Machining Tips for Precision Parts: Expert Guide to High-Quality Manufacturing

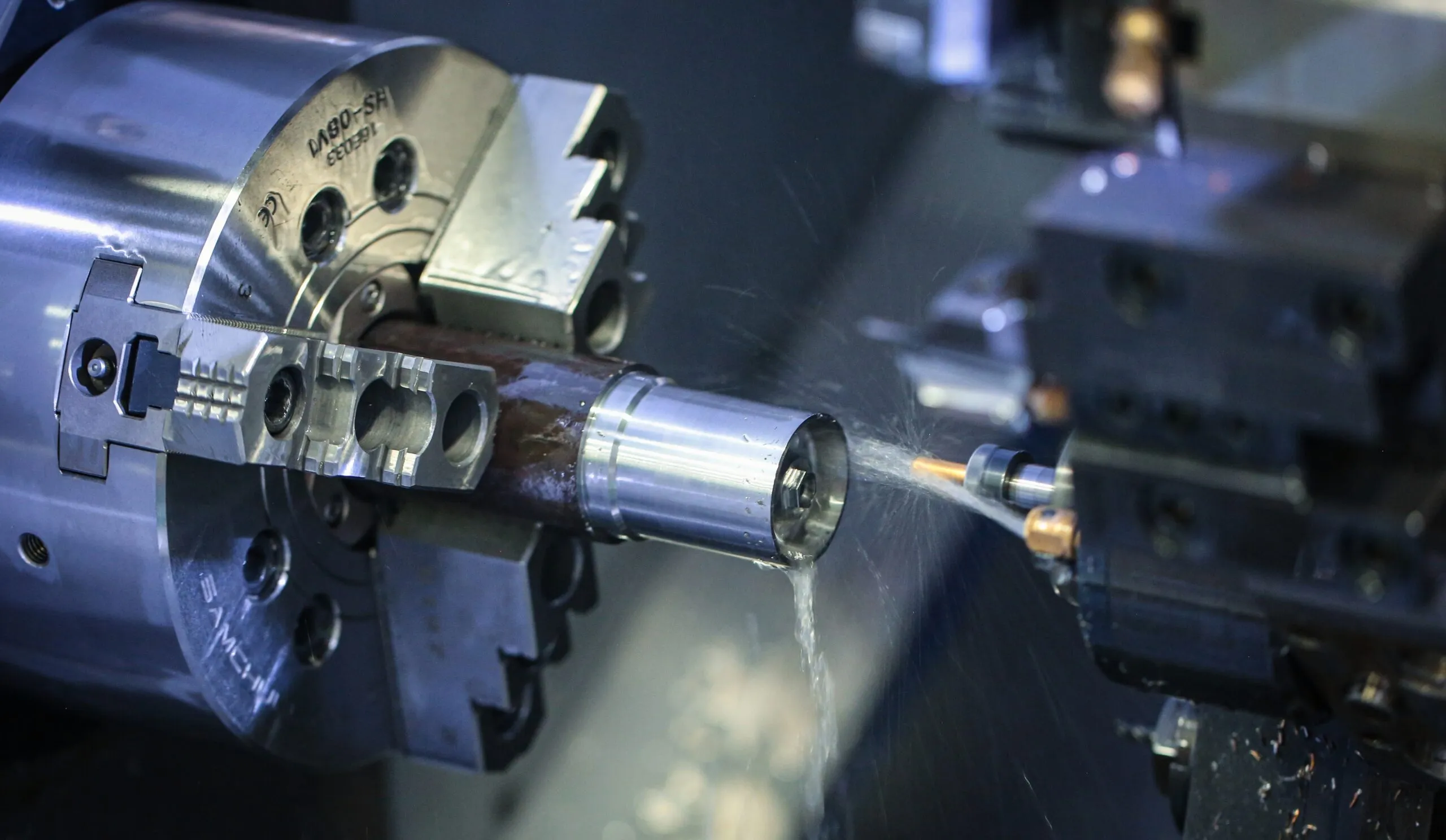

Advanced CNC machining center producing high-precision components

CNC (Computer Numerical Control) machining has revolutionized precision manufacturing, enabling the production of complex parts with exceptional accuracy and repeatability. Whether you're a seasoned engineer or new to CNC machining, understanding the best practices and optimization techniques is crucial for achieving the highest quality parts while maintaining efficiency and cost-effectiveness. In this comprehensive guide, we'll share expert CNC machining tips that will help you optimize your precision parts manufacturing process.

Understanding CNC Machining Fundamentals

Before diving into specific tips, it's essential to understand the fundamentals of CNC machining. CNC machining uses computer-controlled machine tools to remove material from a workpiece, creating parts with precise dimensions and complex geometries. The process involves several key components:

- CAD/CAM Software: Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software are used to create part designs and generate toolpaths.

- CNC Controller: The brain of the CNC machine that interprets G-code and controls machine movements.

- Machine Tools: Various cutting tools including mills, lathes, drills, and other specialized equipment.

- Workholding: Fixtures and clamps that secure the workpiece during machining.

Material Selection for Precision CNC Machining

Choosing the right material is one of the most critical decisions in CNC machining. The material selection affects machinability, tool life, surface finish, and overall part quality. Here are key considerations for material selection:

Common CNC Machining Materials

- Aluminum (6061, 7075): Excellent machinability, lightweight, good strength-to-weight ratio. Ideal for aerospace, automotive, and consumer electronics.

- Stainless Steel (304, 316, 17-4 PH): High corrosion resistance, excellent strength. Suitable for medical, food processing, and marine applications.

- Carbon Steel (1018, 1045): Good machinability, cost-effective. Used in general manufacturing and structural components.

- Titanium (Ti-6Al-4V): High strength-to-weight ratio, excellent corrosion resistance. Essential for aerospace and medical implants.

- Brass and Copper: Excellent electrical conductivity, good machinability. Used in electrical components and plumbing.

- Engineering Plastics (POM, PEEK, Nylon): Lightweight, chemically resistant. Suitable for medical devices and consumer products.

Material Machinability Tips

- Consider material hardness and its impact on tool wear

- Account for material thermal expansion during machining

- Choose materials with consistent properties to ensure repeatability

- Factor in material cost versus performance requirements

- Consider post-machining requirements such as heat treatment or surface finishing

Design for Manufacturability (DFM) Guidelines

Implementing Design for Manufacturability (DFM) principles early in the design process can significantly improve part quality, reduce costs, and accelerate production timelines. Here are essential DFM tips for CNC machined parts:

Wall Thickness and Features

- Maintain uniform wall thickness to minimize distortion and stress

- Avoid extremely thin walls (typically minimum 0.020 inches for metals)

- Design fillets and radii at internal corners to reduce stress concentrations

- Consider tool access and clearance for all features

Tolerances and Precision

- Specify tolerances only as tight as necessary to avoid unnecessary costs

- Standard tolerances of ±0.005 inches are achievable for most features

- Tighter tolerances (±0.001 inches or less) increase machining time and cost

- Consider tolerance stack-up in assemblies

Feature Design

- Design holes with diameters that match standard drill sizes

- Avoid deep holes (depth-to-diameter ratio greater than 10:1) when possible

- Use standard thread sizes for tapped holes

- Minimize the number of setups required to complete the part

- Design parts that can be machined with standard tooling

Tool Selection and Optimization

Selecting the right cutting tools and optimizing their use is crucial for achieving precision and efficiency in CNC machining. Consider these tool selection tips:

Tool Material Selection

- Carbide: Excellent for high-speed machining, good wear resistance. Ideal for steel and stainless steel.

- High-Speed Steel (HSS): Cost-effective, good toughness. Suitable for general-purpose machining.

- Ceramic: Excellent for high-speed machining of hardened materials. Used for finishing operations.

- Diamond: Superior for machining non-ferrous materials and composites. Used for ultra-precision applications.

Tool Geometry Optimization

- Choose appropriate rake angles based on material hardness

- Optimize clearance angles to reduce tool wear

- Select proper helix angles for improved chip evacuation

- Use coated tools for improved tool life and surface finish

- Consider tool diameter relative to feature size for optimal cutting forces

Toolpath Optimization

- Use climb milling for better surface finish and tool life

- Optimize feed rates and spindle speeds for each operation

- Implement adaptive toolpaths for roughing operations

- Use trochoidal milling for difficult-to-machine materials

- Minimize rapid movements to reduce cycle time

Machining Parameters and Optimization

Properly setting machining parameters is essential for achieving optimal results. Key parameters to optimize include:

Cutting Speed (Surface Speed)

The cutting speed determines how fast the tool moves across the workpiece surface. Higher cutting speeds generally improve surface finish but reduce tool life. Consider these guidelines:

- Aluminum: 600-1200 SFM (surface feet per minute)

- Steel: 200-400 SFM

- Stainless Steel: 100-300 SFM

- Titanium: 50-150 SFM

Feed Rate

The feed rate determines how fast the tool advances into the material. Proper feed rate selection balances productivity with tool life and surface finish:

- Higher feed rates increase material removal rate but may reduce surface finish

- Lower feed rates improve surface finish but increase cycle time

- Consider chip thickness and tool engagement when setting feed rates

- Use recommended feed rates from tool manufacturers as starting points

Depth of Cut

The depth of cut affects tool forces, deflection, and surface quality. Optimize depth of cut based on:

- Tool rigidity and length-to-diameter ratio

- Material hardness and machinability

- Machine power and rigidity

- Desired surface finish requirements

- Use multiple lighter passes for finishing operations

Workholding and Fixturing Strategies

Proper workholding is essential for maintaining accuracy and preventing part movement during machining. Consider these workholding tips:

- Design fixtures that provide adequate clamping force without distorting the part

- Use soft jaws or custom fixtures for delicate parts

- Implement multiple setups only when necessary to minimize cumulative errors

- Consider modular fixturing systems for flexibility

- Ensure proper datum references for accurate positioning

- Use vacuum workholding for thin or flat parts

Quality Control and Inspection

Implementing robust quality control processes ensures that parts meet specifications consistently. Key quality control tips include:

- Use calibrated measuring equipment (CMM, micrometers, calipers)

- Implement in-process inspection to catch issues early

- Establish statistical process control (SPC) for critical dimensions

- Document inspection procedures and results

- Use first article inspection (FAI) to verify process capability

- Implement corrective actions for non-conforming parts

Surface Finish Optimization

Achieving the desired surface finish requires attention to multiple factors. Consider these surface finish optimization tips:

- Use finishing passes with lighter cuts and higher feed rates

- Implement proper tool wear management

- Use appropriate cutting fluids for material and operation

- Consider tool runout and balance

- Use appropriate tool coatings for improved surface finish

- Implement proper chip evacuation to prevent surface damage

Cost Reduction Strategies

Optimizing CNC machining for cost-effectiveness doesn't mean sacrificing quality. Implement these cost reduction strategies:

- Design parts that minimize material waste

- Use standard stock sizes to reduce material costs

- Consolidate multiple parts into single components when possible

- Optimize machining sequences to reduce cycle time

- Use appropriate tool grades to balance tool life and cost

- Consider batch processing for similar parts to reduce setup time

"Precision CNC machining is both an art and a science. Success comes from understanding the interplay between design, materials, tooling, and process parameters. By following these best practices and continuously optimizing your approach, you can achieve exceptional results while maintaining efficiency and cost-effectiveness."

Advanced CNC Machining Techniques

For applications requiring the highest precision and complexity, consider these advanced CNC machining techniques:

5-Axis Machining

5-axis CNC machining enables the production of complex geometries in a single setup, reducing cumulative errors and improving accuracy. Benefits include:

- Ability to machine complex shapes and undercuts

- Reduced setup time and improved accuracy

- Better surface finish due to optimal tool orientation

- Shorter lead times for complex parts

High-Speed Machining (HSM)

High-speed machining uses lighter cuts at higher spindle speeds to improve efficiency and surface quality. Advantages include:

- Reduced cycle times for certain applications

- Improved surface finish

- Lower cutting forces and reduced tool deflection

- Extended tool life in certain materials

Multi-Tasking Machining

Multi-tasking machines combine turning and milling operations in a single setup, offering:

- Reduced handling and setup time

- Improved accuracy through single-setup machining

- Ability to produce complex parts efficiently

- Reduced work-in-progress inventory

Choosing the Right CNC Machining Partner

Partnering with an experienced CNC machining service provider can significantly impact your project's success. When selecting a partner, consider:

- Capabilities: Ensure they have the equipment and expertise for your specific requirements

- Quality Systems: Verify they have robust quality control processes and certifications (ISO 9001, AS9100, etc.)

- Experience: Look for experience in your industry and similar applications

- Engineering Support: Choose a partner that provides design for manufacturability feedback

- Lead Times: Confirm they can meet your delivery requirements

- Communication: Evaluate their responsiveness and willingness to collaborate

Conclusion

CNC machining is a powerful manufacturing technology that enables the production of precision parts with exceptional accuracy and repeatability. By understanding the fundamentals, implementing design for manufacturability principles, optimizing tool selection and machining parameters, and partnering with experienced service providers, you can achieve outstanding results in your precision parts manufacturing projects.

Whether you need rapid prototyping or high-volume production, working with a trusted CNC machining partner like Sinbo Precision ensures that your parts meet the highest quality standards while maintaining cost-effectiveness and timely delivery.