CNC Machining Services

Advanced CNC Machining Technology

Sinbo Precision offers state-of-the-art CNC machining services with multi-axis capabilities, providing precise and efficient manufacturing solutions for complex metal components. Our advanced CNC machines ensure exceptional accuracy and surface finish for critical applications.

With our comprehensive CNC capabilities, we can produce complex geometries, tight tolerances, and high-quality surface finishes, making us an ideal partner for aerospace, automotive, medical, and other precision industries.

Why Choose Our CNC Machining Services?

- Multi-axis CNC capabilities (3, 4, and 5-axis)

- Exceptional precision with tolerances as tight as ±0.005mm

- Wide range of materials including metals, plastics, and composites

- Comprehensive post-processing and finishing services

- Expert engineering support for design optimization

Equipment Capabilities

State-of-the-art CNC machinery for various manufacturing needs

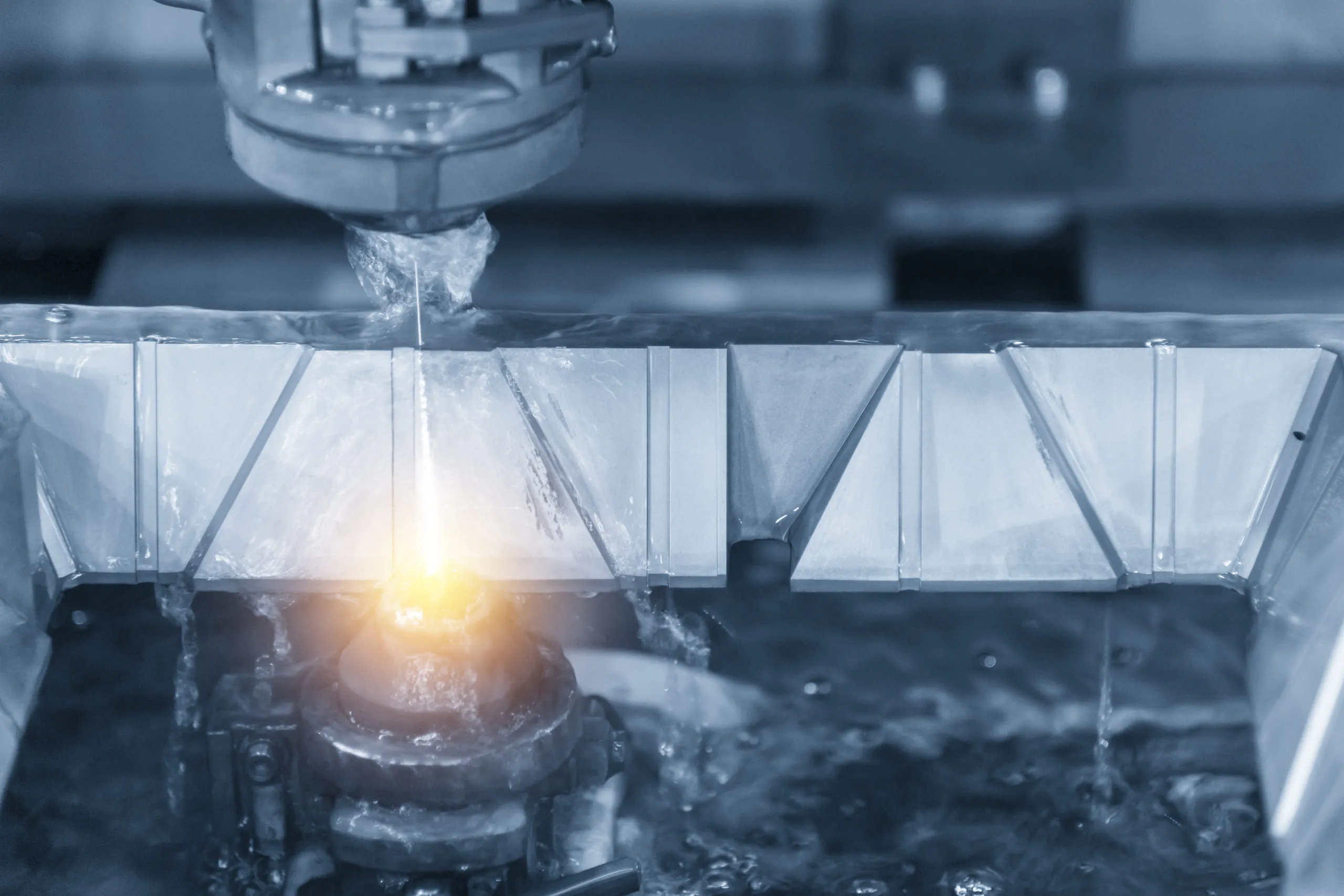

5-Axis CNC Machining

Advanced 5-axis centers for complex geometries and simultaneous multi-surface machining

High-Speed CNC Mills

High-speed vertical and horizontal mills for rapid prototyping and production

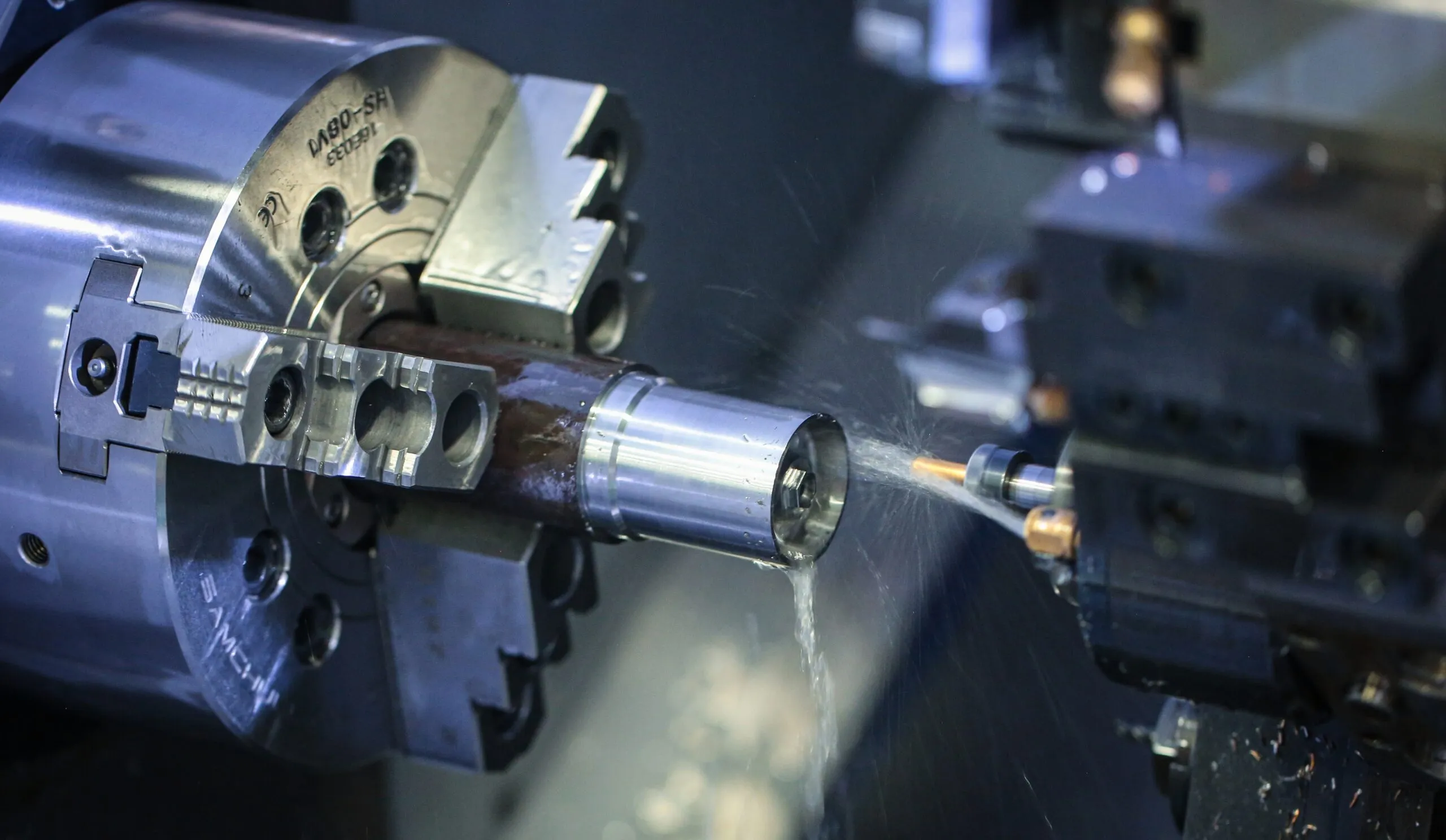

CNC Lathes

Precision turning centers for cylindrical components and rotational parts

Swiss-type Lathe

Ultra-precision turning centers for small-diameter, large-aspect-ratio cylindrical/rotational parts

EDM Machines

Wire and sinker EDM for precision complex features and hard materials

CMM & Inspection

3D coordinate measuring and optical inspection systems

Materials We Work With

Comprehensive material capabilities for diverse applications

Metals

Engineering Plastics

Composites

Tool Steels

Industries We Serve

Precision manufacturing solutions for diverse industry applications

Automotive

Engine components, transmission parts, brake systems

Aerospace

Turbine components, structural parts, fittings

Electronics

Heat sinks, enclosures, connectors

Medical

Surgical instruments, implants, devices

Industrial

Machinery parts, tooling, fixtures

Robotics

Robotic arm components, precision gears, sensor housings

Quality Assurance

Comprehensive quality control processes for consistent precision

Incoming Inspection

Material verification and dimensional checks before processing

In-Process Control

Real-time monitoring and statistical process control

Final Inspection

Comprehensive part verification and documentation

Frequently Asked Questions

Common questions about our CNC machining services

Start Your Manufacturing Project Today

Get in touch with our experts for professional consultation and competitive quotes