What is Injection Molding? Complete Process Guide for Manufacturers

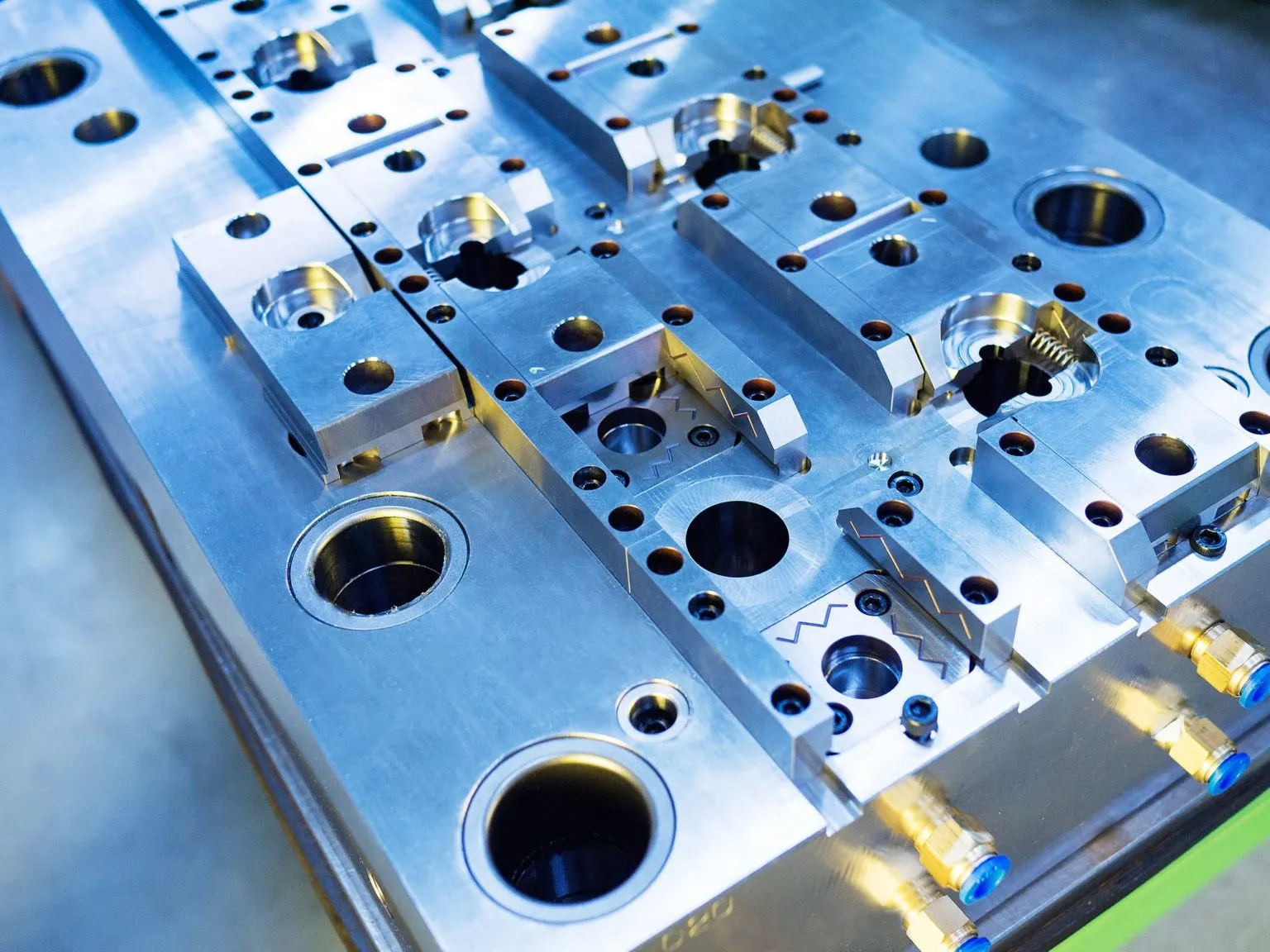

Modern injection molding machine producing high-quality plastic parts

Injection molding is one of the most widely used manufacturing processes for producing plastic parts in high volumes. This versatile manufacturing technique enables the creation of complex, precise, and consistent plastic components for industries ranging from automotive and aerospace to medical devices and consumer electronics. In this comprehensive guide, we'll explore what injection molding is, how the process works, the materials used, and why it's the preferred choice for mass production.

What is Injection Molding?

Injection molding is a manufacturing process where molten plastic material is injected into a mold cavity under high pressure. Once the plastic cools and solidifies, the mold opens, and the finished part is ejected. This process can produce millions of identical parts with excellent repeatability and precision, making it ideal for high-volume production runs.

The injection molding process was first developed in the late 19th century and has evolved significantly with advancements in technology, materials, and automation. Today, it remains one of the most cost-effective and efficient methods for producing plastic parts at scale.

How Does the Injection Molding Process Work?

Understanding the injection molding process is essential for manufacturers and engineers looking to optimize production and achieve the best results. The process consists of several key stages:

1. Clamping

The process begins with the clamping unit, which holds the two halves of the mold together under high pressure. The mold must be securely closed to withstand the injection pressure that will be applied during the next stage. The clamping force required depends on the size and complexity of the part being produced, with larger parts requiring greater clamping force.

2. Injection

Once the mold is clamped, the plastic material (typically in pellet form) is fed into the injection molding machine's hopper. The material is then heated and melted in the barrel before being injected into the mold cavity under high pressure. The injection pressure typically ranges from 10,000 to 30,000 psi, ensuring that the molten plastic fills every detail of the mold cavity.

3. Holding

After the mold cavity is filled, additional pressure is applied to compensate for material shrinkage as the plastic cools. This holding pressure ensures that the part maintains its dimensions and quality. The duration of the holding phase depends on the material and part geometry.

4. Cooling

The cooling phase is critical for achieving the desired part quality. The mold is cooled using water channels or other cooling systems to solidify the plastic. Cooling time typically represents the longest portion of the injection molding cycle and can range from a few seconds to several minutes, depending on part thickness and material properties.

5. Ejection

Once the part has sufficiently cooled and solidified, the mold opens, and the part is ejected using ejector pins or other ejection mechanisms. The ejection system must be carefully designed to ensure the part is removed without damage. After ejection, the mold closes, and the cycle begins again.

Common Injection Molding Materials

The choice of material is crucial for the success of any injection molding project. Different materials offer varying properties in terms of strength, flexibility, heat resistance, and cost. Here are some of the most commonly used injection molding materials:

Thermoplastics

Thermoplastics are the most widely used materials in injection molding due to their versatility and recyclability. They can be melted and solidified multiple times without significant degradation. Common thermoplastics include:

- ABS (Acrylonitrile Butadiene Styrene): Known for its toughness, impact resistance, and ease of processing. Commonly used in automotive parts, consumer electronics, and toys.

- Polycarbonate (PC): Offers excellent impact strength, optical clarity, and heat resistance. Ideal for safety equipment, electronic components, and medical devices.

- Polypropylene (PP): Lightweight, chemically resistant, and cost-effective. Used in packaging, automotive components, and consumer goods.

- Polyethylene (PE): Available in various densities (HDPE, LDPE), offering excellent chemical resistance and moisture barrier properties. Common in containers and packaging.

- Nylon (Polyamide): Provides high strength, wear resistance, and thermal stability. Used in mechanical components, bearings, and gears.

- Polyethylene Terephthalate (PET): Strong, lightweight, and recyclable. Widely used in beverage bottles and food packaging.

Engineering Plastics

For applications requiring superior mechanical properties or specialized performance characteristics, engineering plastics are often chosen:

- Polyoxymethylene (POM/Acetal): Excellent dimensional stability and low friction. Ideal for precision gears and bearings.

- Polyetheretherketone (PEEK): High-performance material with exceptional heat and chemical resistance. Used in aerospace and medical applications.

- Polyphenylene Sulfide (PPS): Offers excellent thermal and chemical resistance. Suitable for automotive and electrical components.

Benefits of Injection Molding

Injection molding offers numerous advantages that make it the preferred manufacturing process for many applications:

High Efficiency and Speed

Once the mold is created, injection molding is an extremely fast process. Cycle times can range from a few seconds to a minute, allowing for the production of thousands of parts per hour. This high efficiency makes injection molding ideal for large-scale production runs.

Cost-Effective for High Volumes

While the initial investment in mold design and fabrication can be significant, the per-unit cost decreases dramatically with higher production volumes. For large production runs, injection molding offers one of the lowest costs per part of any manufacturing process.

Excellent Repeatability and Precision

Injection molding produces parts with exceptional consistency and precision. Modern injection molding machines can maintain tight tolerances, typically within ±0.005 inches, ensuring that every part meets the required specifications.

Design Flexibility

The injection molding process allows for complex geometries and intricate details that would be difficult or impossible to achieve with other manufacturing methods. Features such as undercuts, threads, and living hinges can be incorporated into the mold design.

Material and Color Options

With hundreds of thermoplastic materials available and the ability to color the material during processing, injection molding offers extensive customization options. Manufacturers can choose materials with specific properties to meet their application requirements.

Reduced Waste

Injection molding is a highly efficient process with minimal material waste. Any excess material (sprues, runners, and gates) can typically be reground and reused, making the process environmentally friendly and cost-effective.

Applications of Injection Molding

Injection molding is used across virtually every industry that requires plastic components. Some common applications include:

Automotive Industry

Injection molding produces a wide range of automotive components, including dashboards, bumpers, door panels, and interior trim. The ability to produce lightweight, durable parts makes injection molding essential for modern vehicle manufacturing.

Medical Devices

The medical industry relies on injection molding for producing surgical instruments, drug delivery devices, and diagnostic equipment components. The process's precision and ability to use medical-grade materials make it ideal for critical healthcare applications.

Consumer Electronics

From smartphone cases to computer keyboards, injection molding produces countless components for consumer electronics. The process enables the creation of sleek, functional designs with tight tolerances.

Packaging

Injection molding is widely used for producing bottles, caps, containers, and other packaging solutions. The ability to create complex shapes and incorporate branding elements makes it valuable for product packaging.

Industrial and Construction

Industrial components, construction materials, and hardware often rely on injection molding for production. The process's ability to create durable, high-strength parts makes it suitable for demanding industrial applications.

Design Considerations for Injection Molding

Successful injection molding requires careful attention to design details to ensure manufacturability and part quality. Key design considerations include:

Wall Thickness

Maintaining uniform wall thickness is critical for preventing defects such as warping, sink marks, and voids. Typical wall thickness ranges from 0.040 to 0.150 inches, depending on the material and part size.

Draft Angles

Draft angles (slight tapers on vertical walls) are necessary to facilitate part ejection from the mold. Typical draft angles range from 1 to 2 degrees, with deeper drafts required for textured surfaces.

Radii and Fillets

Incorporating radii and fillets at corners and edges reduces stress concentrations and improves material flow during injection. This enhances part strength and reduces the risk of defects.

Ribs and Bosses

Ribs can be added to increase part stiffness without increasing wall thickness, while bosses provide mounting points for screws or other fasteners. Proper design of these features is essential for structural integrity.

Small Batch Injection Molding Services

While injection molding is traditionally associated with high-volume production, advances in technology have made small batch injection molding increasingly viable. Small batch injection molding services enable manufacturers to produce quantities ranging from 100 to 10,000 parts, bridging the gap between prototyping and full-scale production.

Small batch injection molding offers several advantages for product development and market testing:

- Reduced upfront investment: Lower mold costs compared to production tooling

- Faster time to market: Quick turnaround times for market testing and validation

- Flexibility: Ability to iterate designs and make changes before committing to full production

- Cost-effective: Lower per-unit costs for medium-volume production runs

"Small batch injection molding has revolutionized product development by allowing companies to test and refine their designs before investing in expensive production tooling. It provides the perfect bridge between rapid prototyping and mass production."

Choosing the Right Injection Molding Partner

Selecting the right injection molding partner is crucial for project success. When evaluating potential partners, consider the following factors:

- Experience and expertise: Look for a partner with experience in your industry and similar applications

- Capabilities: Ensure they have the equipment and capacity to handle your project requirements

- Quality systems: Verify they have robust quality control processes and certifications

- Material knowledge: Choose a partner with expertise in material selection and processing

- Communication and support: Evaluate their responsiveness and willingness to collaborate

- Lead times: Confirm they can meet your production timeline requirements

Conclusion

Injection molding is a versatile, efficient, and cost-effective manufacturing process that enables the production of high-quality plastic parts at scale. Understanding the injection molding process, materials, and design considerations is essential for manufacturers and engineers looking to leverage this technology for their projects.

Whether you need high-volume production or small batch injection molding services, working with an experienced partner like Sinbo Precision can help ensure your project's success. Our team of experts is ready to assist with material selection, design optimization, and production to meet your specific requirements.