Small Batch Injection Molding Services Explained: Cost-Effective Production for 100-10,000 Parts

Small batch injection molding enables cost-effective production of 100-10,000 parts

Small batch injection molding services have emerged as a game-changing solution for companies needing production-quality plastic parts in quantities between 100 and 10,000 units. This manufacturing approach bridges the critical gap between prototyping and full-scale mass production, offering businesses the flexibility to test markets, validate designs, and generate revenue without the substantial upfront investment required for traditional high-volume injection molding. In this comprehensive guide, we'll explore everything you need to know about small batch injection molding services.

What is Small Batch Injection Molding?

Small batch injection molding is a manufacturing process that produces plastic parts in quantities typically ranging from 100 to 10,000 units. Unlike traditional injection molding, which is optimized for producing hundreds of thousands or millions of parts, small batch injection molding uses specialized tooling and production techniques to make lower volume production economically viable.

This approach is particularly valuable for companies at various stages of product development, including startups launching new products, established companies testing new designs, and businesses requiring ongoing production of specialized or custom parts. Small batch injection molding delivers production-quality parts using the same materials and processes as high-volume production, but with significantly lower tooling costs and faster turnaround times.

Small Batch vs. Traditional Injection Molding

Understanding the differences between small batch and traditional injection molding is essential for choosing the right manufacturing approach for your project:

Tooling Costs

Traditional injection molding requires expensive hardened steel molds that can cost $20,000 to $100,000 or more, depending on part complexity. These molds are designed to last for millions of production cycles. Small batch injection molding, on the other hand, utilizes rapid tooling techniques with aluminum or softer steel molds that typically cost $3,000 to $15,000, making them much more accessible for lower volume production.

Lead Times

Traditional injection molding tooling often requires 8-16 weeks for design, fabrication, and testing. Small batch injection molding tooling can be completed in 2-4 weeks, dramatically reducing time to market. This faster turnaround is crucial for companies needing to respond quickly to market opportunities or test product concepts.

Production Volume

Traditional injection molding is optimized for high-volume production runs of 100,000+ parts. Small batch injection molding is designed for quantities of 100-10,000 parts, making it ideal for bridge production, market testing, and ongoing production of specialized products with limited demand.

Part Quality

Both traditional and small batch injection molding produce production-quality parts with excellent consistency and precision. The key difference is that small batch molds may have shorter lifespans (typically 10,000-50,000 cycles) compared to traditional molds (millions of cycles), but the parts produced meet the same quality standards.

Benefits of Small Batch Injection Molding Services

1. Reduced Upfront Investment

One of the most significant advantages of small batch injection molding is the dramatically lower upfront investment. By using rapid tooling techniques, companies can:

- Reduce tooling costs by 60-80% compared to traditional molds

- Preserve capital for other business priorities such as marketing and R&D

- Minimize financial risk when launching new products

- Test multiple design iterations without prohibitive costs

- Enter new markets with lower financial barriers

2. Faster Time to Market

Speed is critical in today's competitive marketplace, and small batch injection molding enables faster time to market by:

- Reducing tooling lead times from months to weeks

- Enabling rapid design iterations and improvements

- Allowing companies to respond quickly to market trends

- Facilitating faster product launches and market entry

- Providing the ability to test and refine products before full-scale production

3. Production-Quality Parts

Unlike prototyping methods that may produce parts with different properties, small batch injection molding delivers:

- Production-quality parts using actual production materials

- Consistent dimensions and tolerances across the production run

- Parts identical to what will be produced in mass production

- Accurate representation of final product performance

- Ability to conduct real-world testing with production parts

4. Design Flexibility

Small batch injection molding offers greater design flexibility compared to traditional high-volume production:

- Lower cost to make design changes and modifications

- Ability to test multiple design variations simultaneously

- Opportunity to refine designs based on testing and feedback

- Flexibility to incorporate late-stage design improvements

- Reduced risk of expensive design errors in production tooling

5. Market Testing and Validation

Small batch injection molding provides an excellent platform for market testing and validation:

- Test product-market fit with real customers using production parts

- Gather valuable feedback on product features and quality

- Validate pricing strategies in actual market conditions

- Build brand awareness and customer relationships early

- Generate revenue while refining the product for mass production

Applications of Small Batch Injection Molding

Small batch injection molding services are valuable across numerous industries and applications:

Bridge Production

Bridge production fills the critical gap between prototyping and mass production:

- Meet initial customer demand while production tooling is being built

- Generate revenue during the transition to mass production

- Validate manufacturing processes and quality systems

- Train production teams and establish workflows

- Build inventory for product launch and marketing campaigns

Market Testing and Product Launch

Small batch injection molding is ideal for market testing and product launches:

- Test new product concepts with limited financial risk

- Launch products in specific geographic markets before global rollout

- Evaluate customer response to product features and pricing

- Refine marketing messages based on real product performance

- Establish market presence and brand recognition

Ongoing Low Volume Production

Many products require ongoing low volume production due to market characteristics:

- Specialized or custom products with limited market demand

- Replacement parts for discontinued products

- Medical devices and equipment with niche applications

- Aerospace and defense components with specific requirements

- Industrial equipment and machinery parts

Startups and New Ventures

Startups particularly benefit from small batch injection molding services:

- Launch products with minimal upfront investment

- Validate business models with actual sales

- Build credibility with production-quality products

- Attract investors with market-tested products

- Scale production gradually as demand grows

Small Batch Injection Molding Process

The small batch injection molding process follows the same fundamental steps as traditional injection molding but with some key adaptations for lower volume production:

1. Design and Engineering

The process begins with thorough design and engineering:

- 3D CAD model review and optimization for injection molding

- Design for manufacturability (DFM) analysis

- Material selection based on application requirements

- Tolerance specification and quality requirements definition

- Mold flow analysis to optimize part and mold design

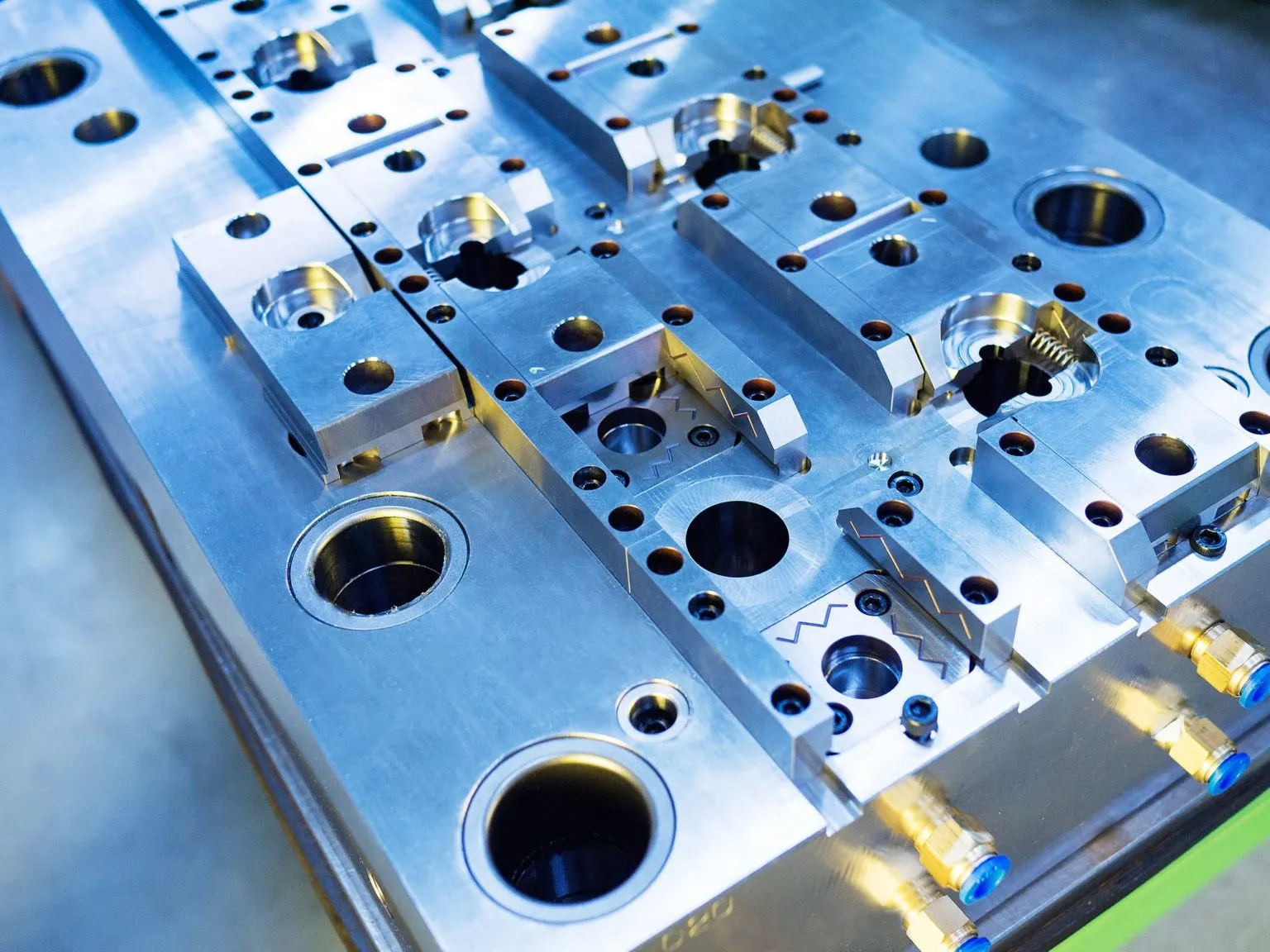

2. Rapid Tooling Fabrication

Rapid tooling techniques are used to create molds faster and more cost-effectively:

- Aluminum or pre-hardened steel mold construction

- CNC machining or electrical discharge machining (EDM) of mold cavities

- Mold base and cooling system design for efficient production

- Ejection system design for reliable part removal

- Mold texturing and surface finish as required

3. Mold Sampling and Validation

Before full production begins, the mold is sampled and validated:

- First article inspection (FAI) to verify part quality

- Dimensional inspection and tolerance verification

- Material testing and validation

- Process parameter optimization for consistent quality

- Customer approval of sample parts

4. Production Run

Once the mold is validated, production begins:

- Injection molding using production-grade materials

- Quality inspection throughout the production run

- Process monitoring to ensure consistent part quality

- Packaging and preparation for shipment

- Documentation and quality records

Rapid Tooling Techniques for Small Batch Production

Several rapid tooling techniques are commonly used for small batch injection molding:

Aluminum Tooling

Aluminum is the most common material for small batch injection molding molds:

- Lower cost compared to hardened steel molds

- Faster machining times reduce lead time

- Excellent thermal conductivity for faster cycle times

- Suitable for production runs of 10,000-50,000 parts

- Easy to modify for design changes

Pre-Hardened Steel Tooling

Pre-hardened steel molds offer a balance between cost and durability:

- More durable than aluminum for longer production runs

- Suitable for 50,000-100,000 parts

- Better wear resistance for abrasive materials

- Higher precision for tight tolerance applications

- Still significantly less expensive than fully hardened steel

Hybrid Tooling

Hybrid tooling combines different materials for optimal performance:

- Aluminum mold base with steel cavity inserts for critical areas

- Cost-effective approach for molds with high-wear areas

- Combines the benefits of both materials

- Extended mold life compared to all-aluminum construction

- Ideal for molds with complex geometries

Material Options for Small Batch Injection Molding

Small batch injection molding supports the same wide range of materials as traditional injection molding:

Commodity Thermoplastics

Common thermoplastics for general applications:

- ABS: Tough, impact-resistant, easy to process

- Polystyrene (PS): Rigid, transparent, cost-effective

- Polypropylene (PP): Lightweight, chemically resistant

- Polyethylene (PE): Excellent chemical resistance, flexible

Engineering Thermoplastics

High-performance materials for demanding applications:

- Polycarbonate (PC): Impact strength, optical clarity

- Nylon (PA): High strength, wear resistance

- Acetal (POM): Dimensional stability, low friction

- PBT: Excellent electrical properties, chemical resistance

High-Performance Plastics

Specialized materials for extreme applications:

- PEEK: Exceptional heat and chemical resistance

- PPS: High thermal stability, flame retardant

- PEI (Ultem): High strength, flame retardant

- LCP: Excellent flow for thin-wall parts

Cost Considerations for Small Batch Injection Molding

Understanding the cost structure of small batch injection molding helps in budgeting and decision-making:

Tooling Costs

Tooling represents the largest upfront cost in small batch injection molding:

- Aluminum molds: $3,000 - $15,000 depending on complexity

- Pre-hardened steel molds: $5,000 - $25,000

- Hybrid molds: $4,000 - $20,000

- Factors affecting cost: part size, complexity, number of cavities, surface finish

Per-Unit Costs

Per-unit costs vary based on material, part size, and production volume:

- Small parts (under 10g): $0.50 - $2.00 per part

- Medium parts (10-100g): $1.00 - $5.00 per part

- Large parts (over 100g): $3.00 - $15.00+ per part

- Engineering materials typically cost 2-3x more than commodity plastics

- Higher volumes reduce per-unit costs through efficiency gains

Additional Costs

Consider additional costs that may apply to your project:

- Design and engineering services

- DFM analysis and optimization

- Material testing and validation

- Secondary operations (assembly, painting, printing)

- Quality inspection and certification

- Shipping and logistics

Design Guidelines for Small Batch Injection Molding

Following design guidelines ensures successful small batch injection molding:

Wall Thickness

Maintain uniform wall thickness for optimal results:

- Typical wall thickness: 0.040" - 0.150" (1-4mm)

- Uniform thickness prevents warping and sink marks

- Gradual transitions for thickness changes

- Consider material flow and cooling requirements

Draft Angles

Include draft angles for proper part ejection:

- Standard draft: 1-2 degrees per side

- Textured surfaces: 2-3 degrees or more

- Deep features: additional draft may be required

- Zero draft possible with side-actions but increases cost

Radii and Fillets

Use radii and fillets to improve part quality:

- Minimum radius: 0.020" (0.5mm) or material thickness/4

- Reduces stress concentrations

- Improves material flow during injection

- Enhances part strength and durability

Ribs and Bosses

Design ribs and bosses for structural integrity:

- Rib thickness: 50-70% of wall thickness

- Rib height: maximum 3-5 times wall thickness

- Boss design for screw assembly

- Proper draft and radii on all features

Quality Assurance in Small Batch Injection Molding

Quality assurance is critical even for small batch production:

First Article Inspection

Comprehensive inspection of initial production parts:

- Dimensional verification against design specifications

- Visual inspection for cosmetic defects

- Material testing and validation

- Functional testing as required

- Documentation and approval process

In-Process Quality Control

Ongoing quality monitoring during production:

- Regular dimensional checks throughout production run

- Visual inspection of parts for defects

- Process parameter monitoring

- Statistical process control when applicable

- Non-conformance identification and correction

Final Inspection and Packaging

Final quality checks before shipment:

- Final dimensional inspection of sample parts

- Visual inspection of all parts

- Proper packaging to prevent damage

- Quality documentation and certificates

- Customer approval before shipment

Choosing a Small Batch Injection Molding Partner

Selecting the right manufacturing partner is crucial for project success:

Experience and Expertise

Look for a partner with relevant experience:

- Experience with your industry and product type

- Expertise in small batch and rapid tooling

- Material knowledge and processing expertise

- Engineering support and DFM capabilities

- Proven track record of successful projects

Capabilities and Equipment

Ensure the manufacturer has appropriate capabilities:

- Injection molding machines suitable for your parts

- In-house tooling fabrication capabilities

- Quality inspection equipment and processes

- Material handling and storage

- Secondary operations if needed

Quality Systems

Verify quality systems and certifications:

- ISO 9001 or equivalent quality certification

- Robust quality control processes

- Traceability and documentation

- Inspection capabilities and equipment

- Commitment to continuous improvement

Communication and Support

Strong communication is essential for success:

- Responsive project management

- Clear and regular communication

- Technical support and engineering expertise

- Transparency about challenges and solutions

- Collaborative problem-solving approach

Lead Times and Pricing

Evaluate lead times and pricing structure:

- Realistic lead times for tooling and production

- Transparent pricing with no hidden costs

- Competitive pricing for your volume range

- Payment terms that work for your business

- Value for money considering quality and service

"Small batch injection molding has transformed how companies approach product development and market entry. By providing production-quality parts with significantly lower upfront investment and faster turnaround times, it enables businesses to test, validate, and scale their products with minimal risk."

Conclusion

Small batch injection molding services offer a powerful solution for companies needing production-quality plastic parts in quantities of 100-10,000 units. By combining the benefits of injection molding quality with reduced tooling costs and faster lead times, small batch injection molding enables businesses to test markets, validate designs, and generate revenue without the substantial investment required for traditional high-volume production.

Whether you're a startup launching your first product, an established company testing a new design, or a business requiring ongoing low volume production, small batch injection molding provides the flexibility, quality, and cost-effectiveness needed to succeed in today's competitive marketplace. By understanding the process, benefits, and considerations outlined in this guide, you can make informed decisions about leveraging small batch injection molding services for your manufacturing needs.

Ready to explore small batch injection molding for your project? Contact our experienced team to discuss your requirements and discover how we can help you achieve your manufacturing goals with cost-effective, high-quality small batch injection molding services.